how to prep a car for paint after soda blasting

Within our purpose built facilities our meticulous team use both bicarbonate of soda and crushed glass to. Bring it back to your place.

Automotive Abrasive Blasting Soda Blasting Sydney Soda Tec

Scrub with a red scotch brite and keep the metal wet as you are scrubbingdo not let the panels dry up as you are washingkeep them wet until final rinse and after rinsing blow dry with clean airblow into all the little holes and crevaces.

. In a Perfect world. Use After Blast after blasting or sanding metal then paint prime or powder-coat. Anything else is less than perfect.

Follow removal of the tarps with a copious tap water wash down of the plantings. Sandblasting is out bc the car is primarily made of 24 gauge sheet metal I think it would deform much to easily I was looking at walnut shell and plastic media plastic media being about double the cost walnut shell media looks to cost about the same as the soda though. Flood all plantings with tap water immediately after blasting.

Only way to neatralize is water warm water works best and dawn dish soap or simple green. If longer storage is planned the parts should be primed with a non lacquer-based primer. One-time-use abrasives are used for applications like ship cleaning that.

If it cannot be perfect let them blast it. Once the metal is clean you will need. Paint shops in my area suggested leaving it alone after soda blasting.

Another minor disadvantage of soda blasting is the cleanup. Spray wipe and repeat until clean. Use Air to blow out any latent soda.

If you need to store the parts temporarily before painting place them in a dry a location as possible. The main advantage of soda blasting is that it is a cost-efficient single-use abrasive. Sand the car to rough the surface 5.

After soda blasting wood furniture a building or some other object you may notice a white powdery film leftover on the surface. Warm or hot soapy water with a sotch brite and preferably using a pressure washer to rince is the best way I have found to remove the soda. To prepare your car for paint youll need to sand away the old finish and add a few coats of primer.

After sandblasting I wipe the entire frame down with a final prep cleanerto remove the excess residue. Proper Surface preparation will properly prepare your substrate for a subsequent finish and leave it in a raw state. Soda blasting will not warp body panels due to the softness of the crystal and the fact that it generates very little or no heat.

Plastic beads for the shell sand for the engine bay. Wash the car down with a vinegarwater solution to remove any of the soda residue. By cleaning shells right back to bare metal you can see exactly what condition the metalwork is in and therefore what work needs to be done for the best restoration.

Baking soda is a base and the dilute vinegar is an acid - so it will neutralize it. Allow our team to assist you with choosing the proper equipment to give you the desired surface prep finish. No matter how fast you get the metal dry oxidation has started.

A lacquer-based primer allows moisture to penetrate the the metals surface causing re. A thorough pressure washing is necessary to remove the soda residue before ANY coatings or fillers are applied. For more info and to purchase.

Be sure you are ready to apply that finish so rust will not occur. BarryK of Southern Polyurethanes said the same thing when I asked him about how to prep. This is very important.

Your media blaster removes the paint and filler from the body spends days cleaning up the media mess and then takes more time in a clean environment like a real paint booth to apply quality epoxy primer. Aqueous cleaners and phosphoric acid clean and etch the metal. Soda Blasting Ltd exists to strip paint filler rust grime and contaminants from your cherished vehicles.

Buff the surface in small circles until you cant see any shiny patches or lines. Also protects against flash corrosion. Soda blasting will remove automotive paint with almost no chance of harming the car.

Baking soda is a wonderful media that allows you to do things that no other media will accomplish but you need to educate yourself about the media and follow a few simple steps after blasting. Prep 2 metal panels with w g remover prep with 80 grit on a da clean againPrime 1 panel with epoxy prime the other with etchPrior to the severe safety and health restrictions put on silica sand the term sand blasting was commonly used. Repeat until clean and no traces of Soda.

Soda blasting will not harm chrome glass pot metal parts like VIN plates rubber seals or bearings. If youre only touching up a small patch use a sanding block but if youre painting the whole car youll want to use an electric sander. Use a phosphate product Like POR-15 METAL READY over the body to coat the metal and protect from rusting.

Although recycling abrasive is the name of the game for most abrasive blasting applications there are a few special applications where it is not needed. Surface Cleaning After Blasting. In my way of thinking the primer depends on the car I am buildingin this case its the frame under the 54 Ranch Wagon and basically none of it would show unless its on a rack and the car was built to drivenot show so I actually brushed on a slightly thinner coat of.

They were equally empathic that soda needs to be fully neutralized before paint. So wash all areas that were soda blasted with a dilute vinegar solution. Second issue is water accelerates oxidation or rust.

It is very difficult to see the oxidation but it has started. I had the same experience JohnC when I looked into this for my car. After BAKING SODA BLASTING what kind of prep work should be done before painting.

WATER is the only way to remove the baking soda. In areas where tarping is not practical start with a pre-soaking of the plantings and ground the day before with tap water. Coating failures after soda blasting can usually be traced back to no pre-paint preparation or poor preparation or incorrect preparation.

That was if not soda-blasting. I have heard of problems with etch primers not working well over top of soda blasted metal probably because the soda neutralizes the acid in the etch primer. Then rinse with water and dry.

With soda blasting theres much less prep work and protection involved.

Soda Blasting Removes Burnt On Carbon Without Profiling The Metal Or Damaging Rings Find Out More Soda Blasting Diy Projects Tutorials Images Diy

Sand Soda Blasting Owens Fabrication

Know The Pros Cons Of Soda Blasting And Sand Blasting By Henry Russel Medium

Midlife Classics Preparing Your Vehicle For Sodablasting

Pin By Dave Pringle On Soda Blasting Soda Blasting Custom Paint Sand

Eastwood 100lb Pressure Abrasive Blaster Abrasive Blaster How To Remove Rust Soda Blasting

Kbs Coatings 58027 Mg Maroon Motor Coater Engine Paint Kit Click On The Image For Additional Details Paint Kit Engineering Caliper Paint

Soda Blasting Vs Sand Blasting Abitl Finishing Inc

Sand Soda Blasting Owens Fabrication

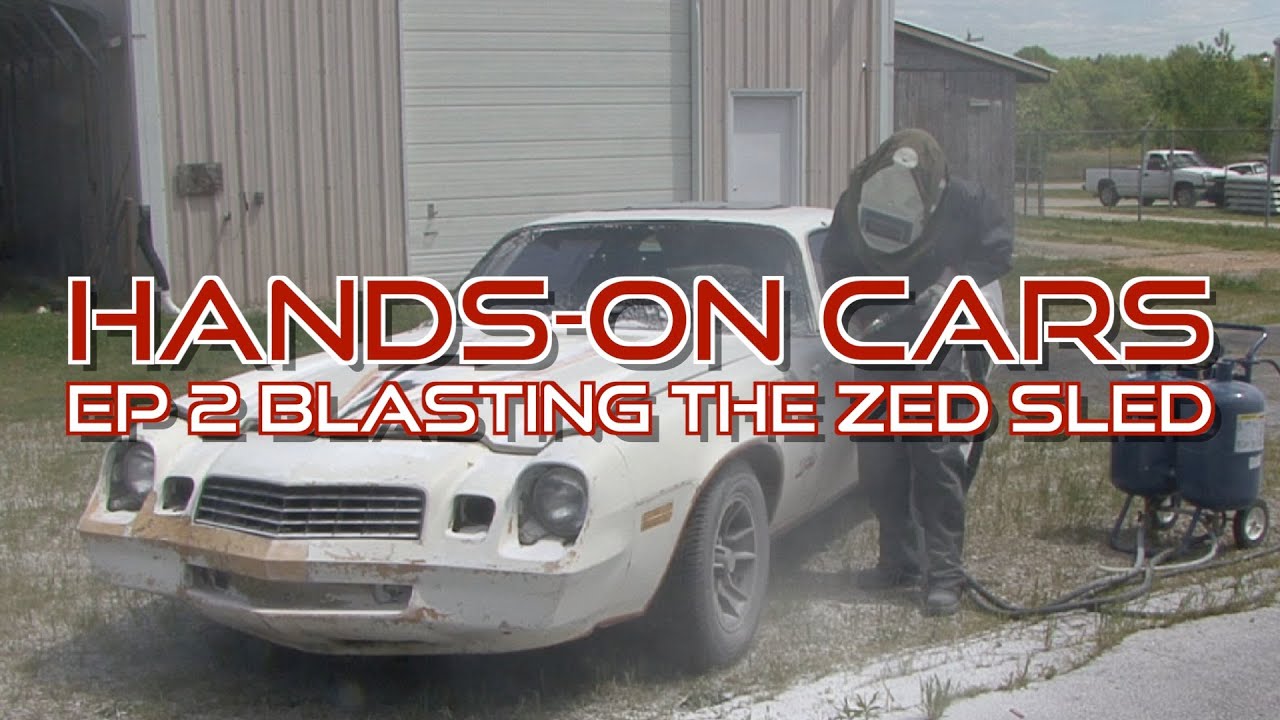

How To Soda Media Blast A Car Hands On Cars 2 From Eastwood Youtube

Soft Blast Photos Indianapolis Indiana Ids Blast

Best Body Panel Paint Removal System Soda Blasting Services

Media Blasting Metal Preparation A Complete Guide In 2021 Classic Car Show Automotive Restoration Classic Cars

Media Blasting Metal Preparation A Complete Guide Classic Car Show Automotive Restoration How To Clean Metal

Media Blasting Removes Rust Paint From The Classic Car

Supergloss Car Coating Spray Rosydelights Car Coating Car Simply Spray